I just updated the print configurations I use to hopefully help with this. I think the stringing is mostly fixed by a) slightly under-heating my filament, and b) telling Cura to retract way more zealously than it normally would. I generally haven't had to do any post-processing on mine.Had a lot of cleanup to do from retraction stringing

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D printed business cards

- Thread starter Andy

- Start date

Are you both using the 0.4mm nozzle? Another thought i had was the letters might be able to get slightly more detail by reducing the extrusion width, I think you can reduce it down to 0.24mm width on a 0.4mm nozzle. I usually go the other way and max it out 0.8mm because that halves your print time if you don’t have any details smaller than 0.8mm but in this case it may help to go the other direction. It would almost double the print time for the cards unless you use the change-at-z plugin to change the width only when it gets to the layers.

DrNezbit

Member

I'm also using a .4mm nozzle, but I usually print around 200-205 and only 50 for my bed. I could definitely try lowering my hotend a bit, I just like to print a little hotter to get the layers to melt together better. For adhesion I just use a light touch of glue stick. It seems to hold well at 50 and warping wasn't an issue. I also have a 0.1mm³ retraction extra prime amount set to compensate for the slight ooze. I've always had a bit of stringing on my prints, but the tiny hairs were enough to mess with the qr code scanning on that one so I had to clean them up a bit. I also just sliced it with my normal profile too though after importing it with your dimensions. I'll have to try to reslice it and see what all exactly I used. I've also been messing with my flow rate occasionally now after experimenting with the dual filament and I think dropping it from 100 to 90-95 also may help too.

I just got my order of amolen and its nice stuff! I did a vase at 0.8mm extrusion width and with the ripples its surprisingly strong. I will definitely be trying your recipe for mixing though! I got the glow in the dark multicolor, firefly green and starry sky.

This was just the “starry sky” filament to test it out.

The starry sky is so dark in daylight I am going to try it as the text and see if that is readable over green and/or multicolor glow for background like yours.

This was just the “starry sky” filament to test it out.

The starry sky is so dark in daylight I am going to try it as the text and see if that is readable over green and/or multicolor glow for background like yours.

So I'm giving this a shot now. I've set the line width to .25mm as a test. It turns out that Cura has a separate setting for "initial layer line width", so that might help that speed you were mentioning, at least a bit. I've arbitrarily set it to 130%, but it seems like these are pretty small changes--setting it to 200% shaves 4 minutes off of the print time.Are you both using the 0.4mm nozzle? Another thought i had was the letters might be able to get slightly more detail by reducing the extrusion width, I think you can reduce it down to 0.24mm width on a 0.4mm nozzle. I usually go the other way and max it out 0.8mm because that halves your print time if you don’t have any details smaller than 0.8mm but in this case it may help to go the other direction. It would almost double the print time for the cards unless you use the change-at-z plugin to change the width only when it gets to the layers.

You can definitely see the difference in the tool path preview, though. Here's .4mm width:

and here's .25mm:

Looks like the time difference is right about where you said it'd be. This is an interesting setting, and I'll definitely have to play with it some more. For shiggles, I sliced it at .8mm, and everything but the print time looks like a disaster. I'm kind of tempted to print it once I see how much of a difference .25mm makes.

Ah that is interesting results! Looking at your slicer preview it doesn't seem like there is anything small enough to make that worth while anymore since most letters and punctuation marks are already 2 lines wide on the 0.4mm nozzle. Thanks for giving it a shot though!

One thing I haven't been able to figure out is how far the range Cura 5 uses for the new Variable extrusion width feature. In your 0.8mm sliced example the three squares for the QR code orientation for example have the same 2 lines of extrusion width for their box but they appear to the be the same 0.4mm width for both. The other areas like the infill are clearly much larger on the 0.8mm though. I wonder if that 0.8mm would look worse? If it's downsizing the extrusion width automatically like it appears to be, I don't think you would actually get much loss of detail, maybe just a rougher background? Hard to tell what would happen since it's running that algorithm over the extrusion width, I'm not sure how these numbers are reflected in the final slicing.

One thing I haven't been able to figure out is how far the range Cura 5 uses for the new Variable extrusion width feature. In your 0.8mm sliced example the three squares for the QR code orientation for example have the same 2 lines of extrusion width for their box but they appear to the be the same 0.4mm width for both. The other areas like the infill are clearly much larger on the 0.8mm though. I wonder if that 0.8mm would look worse? If it's downsizing the extrusion width automatically like it appears to be, I don't think you would actually get much loss of detail, maybe just a rougher background? Hard to tell what would happen since it's running that algorithm over the extrusion width, I'm not sure how these numbers are reflected in the final slicing.

I finally got to play with this, now that a file is on the SD card it's hard to not start another print with a new color combo after taking the first one off. It's addictive!

Your typography work is great Andy, the logo looks amazing! I stuck them in my 3d printed holder and I love the combo. They are a fun one to test filaments with too since it's a quick print and something that can be given away after. I had trouble scanning the QR code on some of mine but I think it's because I set the filament change position too low since I wasn't using Cura and the grey scale layer changes.

I'm attaching the Zip for the business card holder here, it can be printed on it's back with supports inside the card slot. I tried a weird dove tail split for my print in the photo but there was no benefit to that and I don't know why I did it that way. I guess I can say the dovetails work great but it didn't help the printing process, I think I just wanted to play with the splitting tool

Your typography work is great Andy, the logo looks amazing! I stuck them in my 3d printed holder and I love the combo. They are a fun one to test filaments with too since it's a quick print and something that can be given away after. I had trouble scanning the QR code on some of mine but I think it's because I set the filament change position too low since I wasn't using Cura and the grey scale layer changes.

- Wood PLA + Green

- Purple Silk + Gold Silk

- Royal Blue + Gold Silk + Black

- Green + White

- Royal Blue + White + Red

- Night Sky Glow in the Dark. + Neon Yellow

- Magenta Silk + Black + White

I'm attaching the Zip for the business card holder here, it can be printed on it's back with supports inside the card slot. I tried a weird dove tail split for my print in the photo but there was no benefit to that and I don't know why I did it that way. I guess I can say the dovetails work great but it didn't help the printing process, I think I just wanted to play with the splitting tool

Attachments

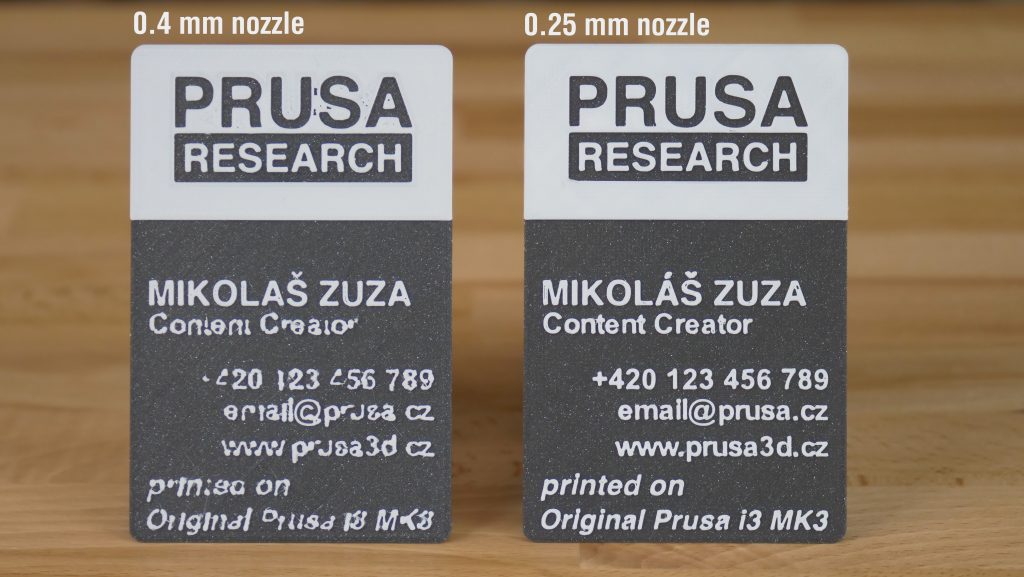

I was reading up on nozzle sizes for 3d printers and I was surprised to see they actually talked about this exact type of print (business cards):

Okay, so yeah duh, of course smaller nozzle would make it better, I guess I just am surprised how much nicer the 0.25mm was for this exact purpose. I might even order some 0.25mm nozzles now, they just kinda pricey for the prusa ones compared to the nice cheap ones for ender 3s. Those results though! So pretty.

-https://blog.prusa3d.com/everything-about-nozzles-with-a-different-diameter_8344/Examples of practical use (0.25 mm)

Printing texts

As already mentioned, the nozzle diameter has a noticeable effect on the printing resolution of the plane parallel to the print surface. This means that a 0.25mm nozzle is suitable for printing detailed text. Let’s compare it to the default 0.4mm nozzle. Despite the fact that ‘Detect thin walls’ is enabled, parts of the letters can be lost during slicing. This won’t happen with a 0.25mm nozzle, so you can use it to print an unusual business card to woo the crowdsIt’s worth mentioning that changing the layer height won’t affect the text legibility.

Slic3r preview shows that the object’s details are too small for the selected nozzle

Left: Business card printed with a 0.4mm nozzle. Right: Same model, printed with a 0.25mm nozzle.

Okay, so yeah duh, of course smaller nozzle would make it better, I guess I just am surprised how much nicer the 0.25mm was for this exact purpose. I might even order some 0.25mm nozzles now, they just kinda pricey for the prusa ones compared to the nice cheap ones for ender 3s. Those results though! So pretty.

Dang, that's my takeaway too--I need to get some .25mm nozzles. Should probably get some .6 nozzles too, for reasons. I hated dealing with it at the time, but when I was troubleshooting my under-extrusion (side-eye at Creality's plastic extruder arms...), I added this mod, and I'm glad I did. I'm less worried about chasing down hotend gaps or putting too much back-pressure on my pressure fitting.

Interesting! I have to admit the original design of having the ptfe go stright against the nozzle is not my favorite. I was dealing with a lot less issues with plastic leaking and heat creep with the microswiss all metal upgrades but this seems like a much easier solution!Dang, that's my takeaway too--I need to get some .25mm nozzles. Should probably get some .6 nozzles too, for reasons. I hated dealing with it at the time, but when I was troubleshooting my under-extrusion (side-eye at Creality's plastic extruder arms...), I added this mod, and I'm glad I did. I'm less worried about chasing down hotend gaps or putting too much back-pressure on my pressure fitting.

After seeing a single E3D nozzle is $15 i think ill try and see if i have any for the enders first, i believe I had bought an assortment a long time ago but not sure what all that included. $10 buys like 20 of the ender nozzles on amazon! Just a 30x price difference between those two!

Holy crap. I was looking at that too, but didn't see how expensive the E3D nozzles were. I thought those were also open source and common; why are they so expensive?After seeing a single E3D nozzle is $15 i think ill try and see if i have any for the enders first, i believe I had bought an assortment a long time ago but not sure what all that included. $10 buys like 20 of the ender nozzles on amazon! Just a 30x price difference between those two!

That is a good point, why are they so expensive? I did find a similar sized pack of a chinese brand that look like the ender style but with the right threads for the e3d blocks. I might have to adjust my z height but I’ll give them a try and see how they do. Not sure what accounts for the difference in shape between the enders and e3d, it seems like the e3d tried to reduce mass by having only the hex for the socket and a tiny V shaped nozzle hole compared to enders having the nozzle V extend much further? I imagine the shape e3d chose has some extra steps in machining with that shape, but is there any benefit or was that to set themselves apart?