DrNezbit

Member

Has anyone tried this or seen it in person?

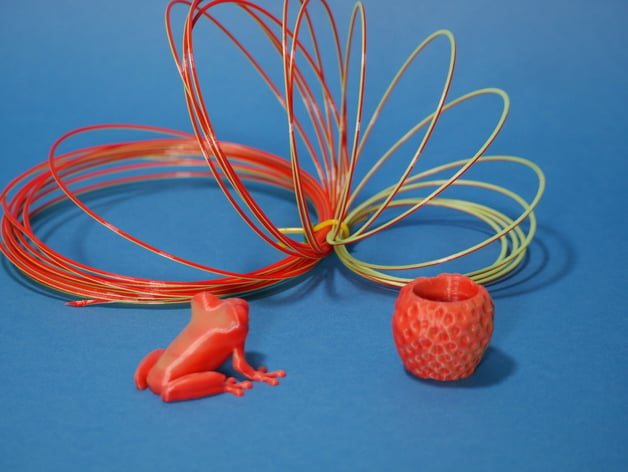

AMOLEN 3D Printer Filament, PLA Filament 1.75mm Dual Color Filament, Silk Red Green 3D Printing Filament 1KG/2.2lb

Video:

Curious if it is as awesome as it looks before I look into ordering some

AMOLEN 3D Printer Filament, PLA Filament 1.75mm Dual Color Filament, Silk Red Green 3D Printing Filament 1KG/2.2lb

Video:

Curious if it is as awesome as it looks before I look into ordering some